The challenge of chronic wounds

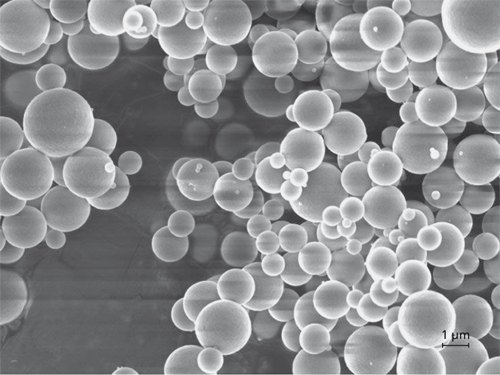

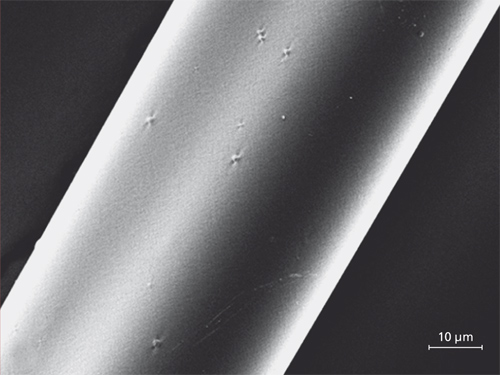

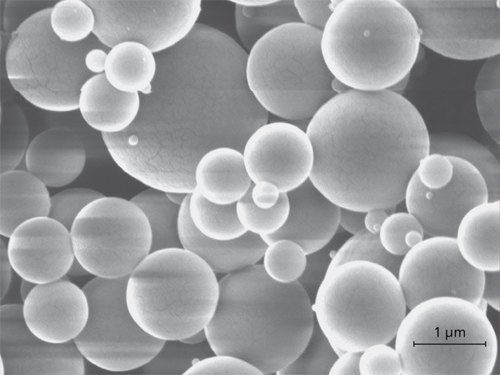

The effective and cost-efficient treatment of chronic wounds is a great challenge in healthcare. Demographic changes have resulted in a constant increase in chronic wounds – above all, diabetic ulcers. Previously, the amputation of extremities and the associated loss in quality of life have often been unavoidable. The development and evaluation of new forms of treatment for chronic skin disorders are therefore extremely important in regard to reducing costs and improving care. For the individual treatment of these chronic wounds we are developing particle-based formulations within the Fraunhofer “Beyond Tomorrow” project “SKIN HEAL”. The particles loaded with active agents can be integrated into commercial wound dressings or directly applied during treatment as pharmaceutical formulations.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB