Inkjet printing is a highly attractive technology whose capabilities are increasingly used for printing functional structures in addition to colour printing. For example, electronic circuit boards can now be produced using printing technology. Rapid prototyping also makes use of inkjet printing to build up objects of any complexity layer by layer, which can be used either as models or as finished components, for example in lightweight construction. Accordingly, inks with a wide variety of properties are increasingly being used for these applications.

Micro-Print – Functional inks for inkjet printing

Range of services

- Formulation of aqueous or solvent-based inkjet inks

- Biofunctional inks

- Inks containing nano- and microparticles

- UV curable inks

- Conductive and semiconductor inks

- Printing of high-resolution structures

Ink formulations for the processing of various functional components

At Fraunhofer IGB, ink formulations are developed for processing a wide range of functional components. In particular, we produce biofunctional inks, for example to make biomolecules available for the production of sensors or medical assays for fast and automated processing. Nanoparticles are another functional component that can be adapted in a variety of ways. Depending on their chemical composition, they introduce different properties such as electrical charge, conductivity, color or fluorescence into an ink. Depending on the requirements, we produce aqueous or solvent-based inks. Any additives required to adjust the rheological properties of the inks are adapted to the properties of the functional components. For the printing of high-precision, flat structural elements, we use a state-of-the-art high-precision printer, the Dimatix Material Printer-3000 (FUJIFILM Dimatix, USA).

Inks containing nanoparticles

Nanoparticles have the potential to transport a wide range of functions: Both the properties of the particle shell, such as the provision of certain chemical groups, and the loading of the particle core with dyes or active components, which are released after printing, for example in contact with water, can contribute to the systematic design of material properties. Fraunhofer IGB develops inkjet-compatible formulations for the targeted and structured application of suspensions of functional nanoparticles. For example, we have developed a washable, water-based ink for coating surfaces with electrically charged nanoparticles. Glass carriers printed with a layer of positively charged nanoparticles are being tested as substrates for the development of sensitive rapid tests based on nucleic acid microarrays microarrays.

Biofunctional inks

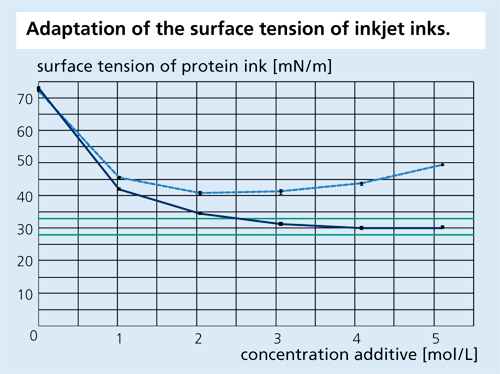

In biotechnology, too, there is a growing demand for processes for reproducible and automatable processing of materials - especially for the processing of biological or biofunctional materials. Fraunhofer IGB has developed an ink formulation for processing proteins while preserving their native functionality. These biofunctional inks can be used to make certain areas on a substrate attractive for the adhesion of different cell types. Photocrosslinkable protein inks will one day be used to create three-dimensional carrier structures for cells. We have used water-soluble and protein-compatible components to adjust the viscosity and surface tension of the inks (see diagram).

Another example is the use of the inkjet printing process for the development of biomaterials that can be used for cell assays: By adding particles of different sizes to the ink we can, for example, create fields with different topographies and investigate their influence on cell adhesion.

Outlook

Inkjet technology enables the material application of expensive and high-quality substances with pinpoint accuracy and virtually no loss. Fraunhofer IGB is currently working on ink formulations made of UV-A-crosslinkable biopolymers for use in 3D inkjet printing processes.

Funding

We would like to thank the Federal Ministry of Education and Research (BMBF) for funding the project "Micro-Print - Printing technology for innovative functional surfaces", funding code 01 RI 0618A.

Project partners

- Fraunhofer Institute for Manufacturing Engineering and Automation IPA, Stuttgart

- SCHOTT Technical Glass Solutions GmbH, Jena

- Inomat GmbH, Neunkirchen

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB