Metabolic pathway engineering refers to the targeted modification of the metabolism of microorganisms in order to optimize the desired production of substances in such a way that certain substances can be produced in increased amounts or purer form. This enables more sustainable, resource-saving production processes. Fraunhofer IGB is working on the targeted modification of yeast strains that are to be used for dicarboxylic acid synthesis.

Optimization of whole-cell catalysts by metabolic pathway engineering

Development of new biocatalysts for the production of long-chain dicarboxylic acids

Long-chain dicarboxylic acids can be used in many industrial applications as platform chemicals, for example in the polymer industry for the production of polyamides or polyesters. Dicarboxylic acids are mainly produced by chemical processes. In the chemical process, petrochemical raw materials are used for synthesis, and long-chain dicarboxylic acids (> 12 carbon atoms) are difficult to synthesize chemically.

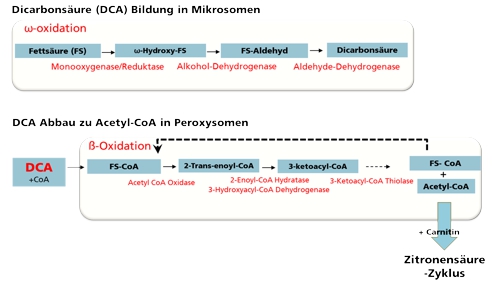

Alternatively, certain yeast strains can be used for dicarboxylic acid production. These can convert alkanes or fatty acids into dicarboxylic acids with a corresponding chain length. The production of dicarboxylic acids in yeast takes place via the so-called omega-oxidation pathway, but at the same time the dicarboxylic acid formed is further metabolized in the beta-oxidation pathway of the yeast and used for energy production.

To prevent degradation of the dicarboxylic acids formed in the cell and to ensure complete conversion of fatty acids as renewable raw materials into dicarboxylic acids, strategies must be developed to block the beta-oxidation pathway in the cell. One possibility is the deactivation (knock-out) of genes of the beta-oxidation pathway using genetic engineering methods.

Such a modified yeast strain is already known from literature and achieves concentrations of over 100 g/l of long-chain dicarboxylic acids in fermentative processes (Picataggio et al., 1992, Metabolic engineering of Candida tropicalis for the production of long-chain dicarboxylic acids. Bio/Technology. 10: 894 - 898). Since this yeast strain is the yeast Candida cenakerosene, its use for the industrial production of long-chain dicarboxylic acids is limited.

Fraunhofer IGB is therefore working in the EU-funded BioConSepT project to provide new, microbiologically harmless production strains for dicarboxylic acid production.

Objectives and strategies

At Fraunhofer IGB we want to use biocatalysts to ensure economical, sustainable dicarboxylic acid production. Therefore, we are working on providing new, microbiologically harmless production strains that can be used as whole cell catalysts in an integrated process for the conversion of fatty acids. Selected strains are genetically modified by metabolic pathway engineering to increase the dicarboxylic acid yield. Furthermore, the possible uses of vegetable oils as a regenerative raw material for the production of dicarboxylic acids, which are not in competition with the food industry, are investigated.

Results and outlook

Various microbiologically harmless yeast strains were identified as potential dicarboxylic acid producers. Fraunhofer IGB is currently working on the genetic modification of a Pichia strain. The genes for the omega- and beta-oxidation pathway were elucidated in yeast using sequence analyses and the genes for the targeted deactivation of the beta-oxidation pathway (knock-out) were identified. The first beta oxidation-deficient strains have been produced and are currently being investigated for the formation of long-chain dicarboxylic acids.

Publications

Werner N, Dreyer M, Wagner W, Papon N, Rupp S, Zibek S. 2016. Candida guilliermondii as a potential biocatalyst for the production of long-chain dicarboxylic acids. Biotechnology Letters. https://doi.org/10.1007/s10529-016-2264-3

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB