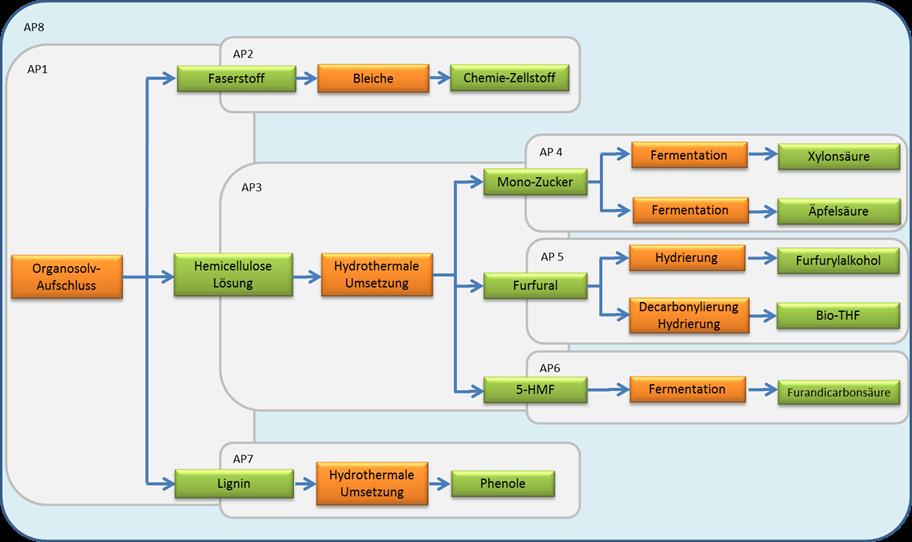

Within the framework of the KomBiChemPro project, the results of various application-oriented development work on the material use of renewable raw materials, especially from lignocelluloses, are to be brought together, combined with new approaches from research and demonstrated in an integrated concept. This should lead to a breakthrough in the implementation of these technologies. The most important aspect here is the production of marketable products in demand through robust, efficient and integrated process control, so that broad applicability and competitiveness with petrochemically produced platform chemicals is guaranteed. In the KomBiChemPro project, the entire process chain of the material use of lignocellulose is examined. All individual results from the laboratory and pilot plant are transferred to the pilot plant of the Fraunhofer CBP, where the entire process chain is mapped. Thus the utilization of the cellulose, hemicellulose and lignin fraction is viewed holistically.

KomBiChemPro - Fine and platform chemicals from wood by combined chemical-biotechnological processes

The Industrial Biotechnology Group of the Fraunhofer IGB will carry out the fermentation development for the production of xylonic acid and malic acid from the C5 sugars of the hemicellulose fraction. The laboratory and pilot plant scale experiments and the scale-up calculations for the fermentation of malic acid and xylonic acid will be carried out by the Industrial Biotechnology (WBT) group in Stuttgart. The colleagues in Leuna then use the protocols that have been prepared to carry out the fermentation on a 10 m³ scale.

Malic acid

There is a steadily growing market for malic acid, as it is used in the food and beverage industry. Here, malic acid serves as a supplier of the acidic taste in products such as jams and juices or it is used to improve the shelf life of baked goods. But malic acid also has considerable potential as a building block in the chemical industry. Together with succinic and fumaric acid it belongs to the group of C4-dicarboxylic acids. C4 acids can be converted into 1,4-butanediol (BDO) - an important precursor for further conversion into a wide range of chemicals, including plastics, polymers and resins for use in e.g. golf balls to printing inks and cleaning agents. The biotechnological production of malic acid is being established by the Industrial Biotechnology Group at the Fraunhofer IGB using Aspergillus strains that have G.R.A.S. status.

Xylonic acid

Xylonic acid is a cost-effective alternative to gluconic acid and avoids the problems of competition between the use of gluconic acid in the food industry or the chemical industry. Furthermore, xylonic acid can be used as a versatile platform chemical, e.g. as a complexing or chelating agent and as a precursor for compounds like copolyamides, polyesters, hydrogels and 1,2,4-butanetriol. So far, there is no market for D-xylonic acid, so the incentives for developing and scaling up production processes have been low. However, with the increasing need to replace petro-based chemicals and glucose-based compounds such as gluconic acid with alternative chemicals, interest in large-scale production will grow. The fermentative production of xylonic acid will be carried out with Gluconobacter sp. and Pseudomonas sp. The necessary establishment of a suitable fermentation process and the determination of dimensionless parameters such as stirrer circumferential speed and kLa are carried out at Fraunhofer IGB by the Industrial Biotechnology group.

Fermentation development

Within the project KomBiChemPro, the Industrial Biotechnology Group of the Fraunhofer IGB will deal with fermentation development on laboratory and pilot plant scale and subsequently carry out scale-up to the 10 m³ scale. During the scale-up, geometric similarity between the different size designs and material similarity should be ensured for the substance systems under consideration. In addition, the process conditions should be transferred to the larger scale with the aid of mostly dimensionless, scale-invariant key figures, e.g. kLa values and the stirrer circumferential speed. These conditions are taken into account at Fraunhofer IGB during the development of the new process and can be validated on a technical scale in cooperation with Fraunhofer CBP.

Project information

Project title

KombichemPro - Fine and platform chemicals from wood by combined chemical-biotechnological processes

Project duration

November 2015 – May 2018

Cooperation partners

- German Biomass Research Centre gemeinnützige GmbH DBFZ

- Fraunhofer Center for Chemical-Biotechnological Processes CBP (Coordinator)

- Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, Stuttgart

Subcontracts

- Thuenen Institute for Wood Research

- Max Planck Institute for Dynamics of Complex Technical Systems

- University of Stuttgart, Institute for Interfacial Engineering and Plasma Physics IGVP

Promotion

We would like to thank the Federal Ministry of Education and Research (BMBF) for funding the project "KomBiChemPro fine and platform chemicals from wood by combined chemical-biotechnological processes", grant no. 031B0083A

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB