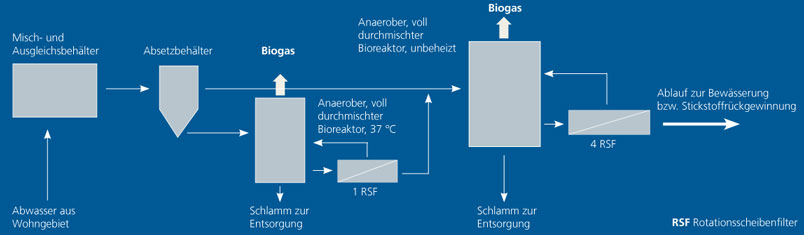

Results from the first pilot plant in Knittlingen’s newly developed estate and from a further Fraunhofer IGB test plant have shown that anaerobic wastewater purification works better when solids are separated before the wastewater is purified. A sedimentation tank has been set up to manage this process

DEUS 21: Anaerobic wasterwater purification in demonstration projects in Knittlingen

Fermenting solids

Detached solids are treated separately at 37 °C using the high-load digestion method developed at the Fraunhofer IGB combined with integrated microfiltration. This gives a yield of up to 5,000 liters of biogas per day. Hydraulic residence time in the reactor is approx. 10 days. Residence times for solids can be chosen freely to a certain extent by removing the filtrate but are significantly longer.

Anaerobic wastewater purification

The overflow of the sedimentation tank (approx. 99 percent of the inflow) is treated in an unheated, complete-mix bioreactor with a volume of 10 m3. Effluent leaves the reactor through four parallel rotating disk filters with pore diameters of 0.2 µm. At present, the microorganisms needed for anaerobic wastewater purification have to be cultivated specifically because there are no plants in Germany which treat communal wastewater anaerobically at low temperatures to provide the microorganisms. For this reason, the load of the bioreactor was increased in slow steps.

Excellent purification – less sludge

The chemical oxygen demand (COD) of the effluent was kept constant at under 150 mg/l for the first time in the summer of 2009 at reactor temperatures of between 22 and 27 °C. This is the limit set by the authorities for purification plants serving less than 1,000 inhabitants. For more than a month, it was even possible to keep this figure under 120 mg/l. In fall/winter of 2009 at reactor temperatures between 13 and 19 °C, figures were constantly under the limit of 150 mg CSB/l although the concentration of methane bacteria in the bioreactor was still relatively low at that time. In fall/winter, the minimum residence time for wastewater in the bioreactor was 36 hours. Inflow concentrations were between 400 and 1,100 mg COD/l and the average degree of decomposition was 85 % for the mentioned time periods. A maximum yield of 2,000 liters biogas was produced per day. In summer, the biomass increased by nearly 5.5 kg (weighed as dry matter) within two months. Based on the usual dewatering to 25 percent of dry matter, this corresponds to a sludge volume of 22 liters in need of disposal. This equals only 10 percent of the amount of excess sludge which can be expected from an activated sludge process. Since it was put into operation in March 2009, the membrane filter has only been cleaned by the automatic back-flush with filtrate. A chemical cleaning process took place for the first time in April 2010.

Biogas production

With the purely anaerobic technology, most of the organic components found in wastewater can be converted into biogas. Up to now, we have been able to produce 40 to 60 liters of biogas per resident and day while conventional wastewater purification by sludge digestion yields approx. 25 liters of biogas per person and day. The energy content of the biogas produced when wastewater is purified anaerobically is more than 100 kWh per resident and year. If one considers that approx. 30 kWh of electric energy is needed per resident and year to run a large treatment plant together with the same amount again of thermic energy, then the gain of 100 kWh per resident and year obtained with anaerobic technology proves that such a plant could at least be run independent of exterior energy sources.

The present pilot plant in Knittlingen, built for demonstration purposes only, is too small to produce the amounts of biogas needed to run conventional systems e.g. in a combined heat and power plant or with a Stirling engine. However, burning puts it to good use by providing thermic energy for the wastewater purification process.

Funding

We would like to thank the German Federal Ministry of Education and Research (BMBF) for funding the project "Decentralized Urban Infrastructure Systems DEUS 21", promotional reference 02WD0850.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB