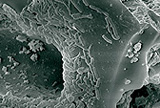

The processing of metallic materials unavoidably involves the production of waste water from cooling lubricants. The waste water is mostly a mixture of aqueous, oily and particulate components. Before disposal of used cooling lubricants conventionally they are processed by ultrafiltration. The filtrate which is the aqueous phase, contains dissolved toxic metals that might be present in too high concentrations.

Objective

Therefore, before the aqueous phase can be discharged into the drainage ditch, concentrations of dissolved metals have to be reduced below the legal limits. To date this has been realized by chemical precipitation, which is disadvantageous from the economical and ecological point of view. Under contract to DaimlerChrysler AG, Fraunhofer IGB is currently developing a biotechnical process as an alternative for this conventional separation technique.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB