Düsseldorf, Gemany / October 08, 2025 - October 15, 2025

K | Fair

International Trade Fair for Plastics and Rubber

Hall 7, floor 0 / booth C05

International Trade Fair for Plastics and Rubber

Hall 7, floor 0 / booth C05

The plastics industry is one of Germany's most important sectors. The industry has earned its strong position, even by international standards, not only through production but also through research and development in the field of plastics. At the world's leading trade fair “K,” 13 Fraunhofer entities will present innovative, sustainable, and efficient approaches, solutions, and developments for plastics processing.

Bio-based plastics are a unique source of sustainable alternatives to fossil-based polymers. They offer access to exclusive functionality and can be produced in a resource-efficient and climate-friendly manner. The synthesis of material building blocks from renewable and domestic raw materials and the production of functional materials play an important role in sustainability in terms of resilience and sovereignty.

Bio-based plastics open up material spaces that are not accessible in the same way through fossil-based chemistry. At Fraunhofer IGB, we use the molecular diversity of bio-based monomer building blocks and biopolymers to develop new materials based on the principles of sustainable chemistry. It is important to us that the integration of bio-based components leads to a functional advantage.

Our services for the development of biopolymers and biobased polymers cover the entire innovation chain: from the provision of raw materials from biomass or CO2 and the synthesis of biobased monomers and additives in the laboratory, to polymerization in an application-oriented pilot plant and plastics processing.

We showcase representative bio-based polymer building blocks and polymers that we intend to develop further with interested corporate partners in order to fill an important gap in the market and establish these new materials there.

The BioCat branch of Fraunhofer IGB with its Laboratory for Technical Biopolymers (LTBP) covers the entire process chain from the synthesis of biobased monomers and additives in the laboratory, through polymerizations in an application-oriented pilot plant, to processing in plastics technology. Supplemented by issues of biodegradability, the LTBP closes the cycle from natural substance, via material, back to natural degradation products and supports industrial companies in the development of innovative, sustainable materials and processes.

Are you looking for a partner to develop more sustainable products? We would be delighted to support you in analyzing your raw and residual materials and developing new materials for your applications.

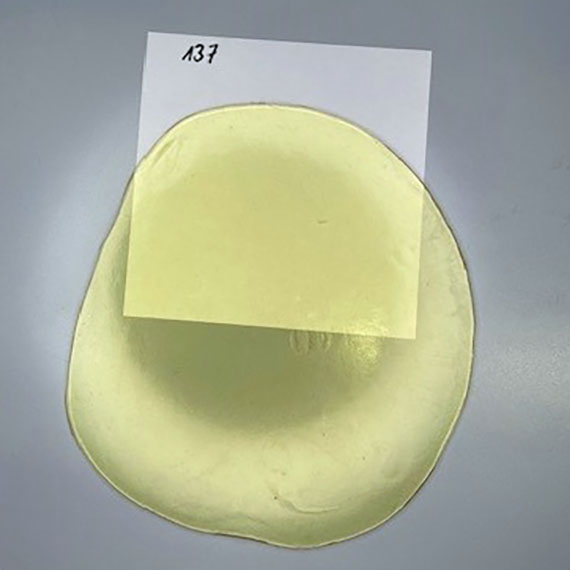

Our caramides (Caramid-R® and Caramid-S®) are 100 percent biobased polyamides produced from a residue of cellulose production: the monoterpene (+)-3-carene. Caramid-R® is amorphous, transparent and has a glass transition temperature of up to 120°C. Caramide-S® has a glass transition temperature of up to 115°C and a melting point of 280°C. Unlike commercial biobased polyamides, our caramides can be prepared by anionic ring-opening polymerization, which enables the production of cast polyamides.

Due to their special chemical structure, these polyamides have exceptional thermal properties that make them interesting for numerous applications ranging from mechanical engineering — for example, for gears — to safety glass, polyamide foams, safety textiles, and even surgical suture material. Filaments, foams, and plastic glasses have now been produced from Caramid®.

There is a high demand for bio-based additives in order to increase the proportion of renewable raw materials in the plastics industry. At the same time, no completely convincing, bio-based comprehensive systems have yet been found for new, bio-based polyesters such as PLA, PEF, or PHA that can match petrochemical additives in terms of price and performance. At Fraunhofer IGB, residues from the pulp industry, natural small biomolecules, proteins, and biogenic polymers are chemically modified and specifically adapted to the corresponding biopolymers as additives. The defined chemical structures of the target molecules are intended to combine the positive properties of industrial fossil and bio-based plasticizers.

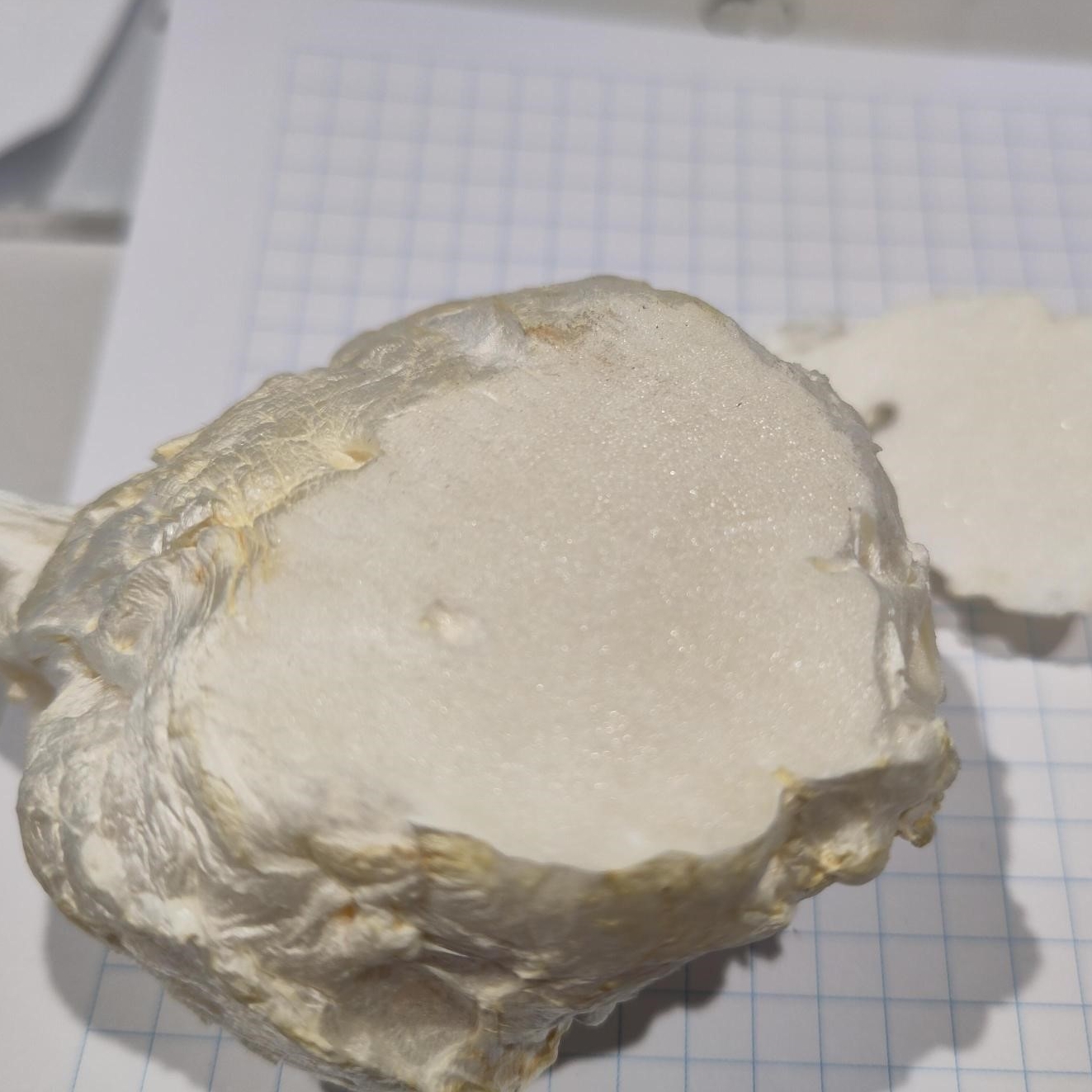

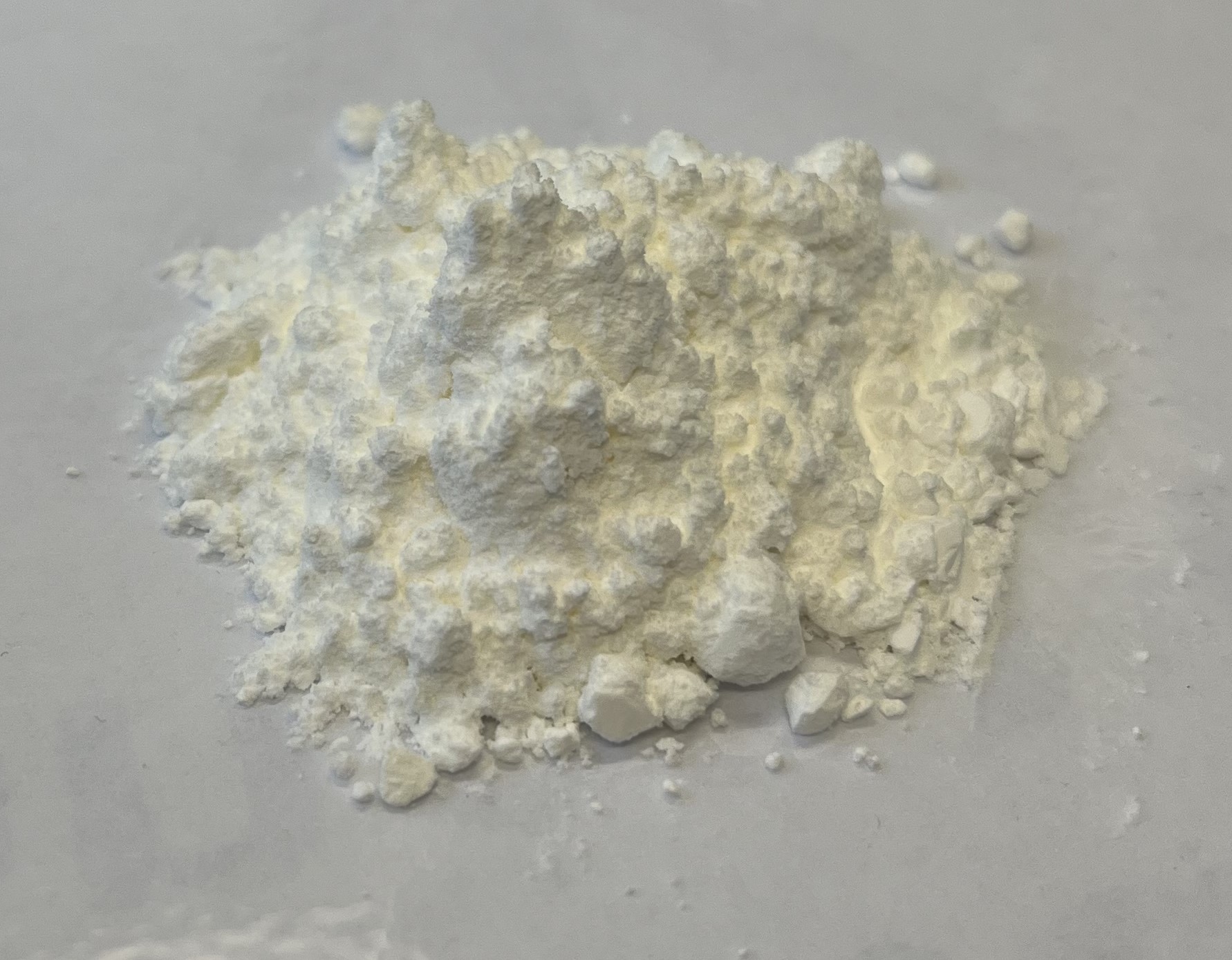

Polyethylene furanoate (PEF) is a bio-based polymer promising to replace fossil-based PET in the future. An essential prerequisite is that the starting material 2,5-furanedicarboxylic acid (FDCA) is available in high purity. Fraunhofer IGB has succeeded in developing a new purification process for FDCA. The purified FDCA was polymerized on a small scale for quality control and then polymerized on a multi-kilogram scale at the DITF and spun into fibers.

In the Tape2Grape project, a multifunctional, biobased and biodegradable grafting tape is being developed. With the targeted use of bioactive components, the woody plants are to be actively supported in the healing process. Due to its biodegradability, the tape can remain in the growing area after application and decompose, as it is not harmful to the environment. Thus, Tape2Grape represents an economic and ecological added value in commercial as well as in organic fruit growing.

Plastisol refers to dispersions of a powdered thermoplastic polymer in a liquid plasticizer and, if necessary, additives. The Bioplastisol project is developing innovative, bio-based, and biodegradable plastisols that have the long-term potential to replace the widely used fossil-based PVC plastisols in many applications. These bioplastisols are not yet established. The project provides access to widely applicable materials that are suitable for on-demand production processes.

The advantages of the new material will be demonstrated through the development of biodegradable fishing lures, and the bioplastisols will be equipped with additives accordingly. Many fishing lures are lost on a large scale during use, have a negative impact on the environment, and are sometimes taken up by fish and other aquatic organisms.