Wastewater fit for a swim

Heidelberg-Neurott, a settlement with 60 inhabitants and not connected to the public sewerage system, now has its own decentralized membrane sewage plant. Connection to the central sewage treatment plant for the area was a more expensive option than construction. Developed and designed by the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, it is the first sewage plant in Germany to use ultra-modern membrane technology in pre- and post-purification. The purified effluent is second to none in terms of quality: through the use of membrane filters the water is almost free of microorganisms, thus fulfilling the requirements of the EU Bathing Water Quality Directive. The quality of the effluent is better than that prescribed for large-scale sewage plants. The Neurott membrane sewage plant was inaugurated on December 17, 2005.

Neurott is a small village situated in a rural area south of Heidelberg. It has a population of sixty, a couple of farms, and an inn which is a popular tourist destination in the summer. This bucolic idyll was clouded only by the lack of “proper” sewage treatment facilities. Up to now, domestic wastewater and excrement were collected in septic tanks, whose contents had to be disposed of on a regular basis. Each emptying, however, polluted the environment because nitrogen-rich wastewater got into soil and ground water. This is now the stuff of history. Heidelberg-Neurott has become the recipient of its own small sewage plant, designed for 100 population equivalents.

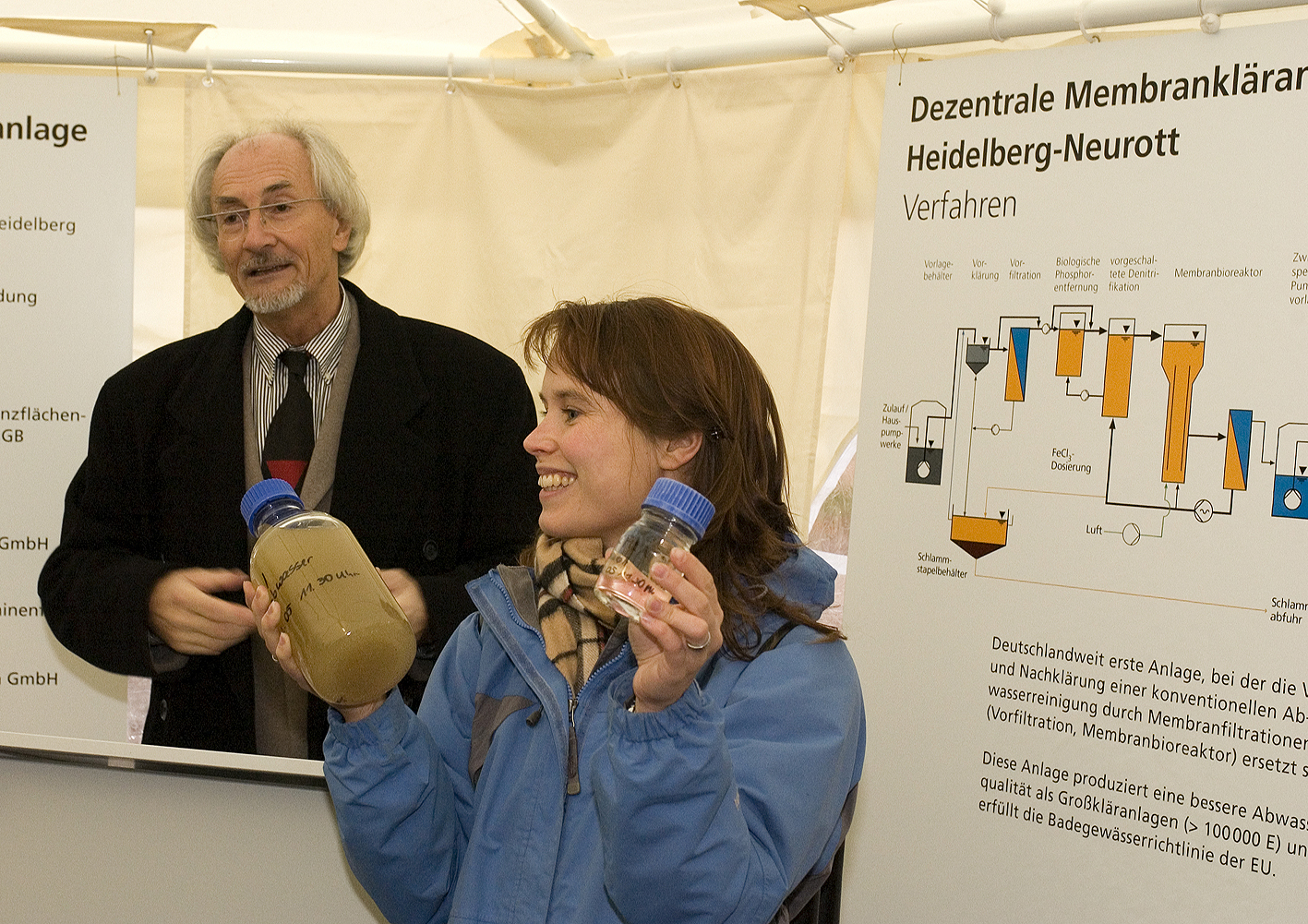

On December 17, 2005, the chairman of the Abwasserzweckverband Heidelberg (Heidelberg Municipal Association for Sewage Treatment) and First Mayor of the city of Heidelberg, Professor Raban von der Malsburg, and Tanja Gönner, Baden-Württemberg's Minister of the Environment, inaugurated Germany’s first semi-decentralized membrane sewage plant featuring membrane filtration and biological elimination of nitrogen. Ultra-modern technology for rural areas, developed and designed by the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB in Stuttgart. The water leaving the sewage plant is cleaner than that of conventional large-scale plants – it easily fulfills the quality requirements for the effluent discharge of plants designed for over 100,000 population equivalents. Taking the example of chemical oxygen demand (COD): in conventional small sewage plants COD must be below 100 milligrams per liter, while large sewage plants (> 100,000 population equivalents) must achieve a COD below 75. The membrane sewage plant in Neurott, by comparison, achieves a COD notably below 50.

Sufficient reasons for the Heidelberg Municipal Association for Sewage Treatment to avoid transporting sewage from the remote village through kilometers of pipes to the nearest main sewage plant. The more so, as connection to the public sewerage system would have been much more expensive. The inhabitants of Neurott were thus spared lengthy civil engineering works. Instead, each house received a small pump, which leads sewage to the influent storage tank of the new plant. All the plant’s technical installations are located in the former equipment house of the local fire brigade.

From this storage (mixing and equalizing) tank the untreated domestic wastewater is pumped via a preliminary settler into the preliminary filtration. Here the raw wastewater is separated into a solid-free and carbon-poor filtrate and a particle-rich bleed. The watery filtrate is first treated to remove phosphate and then biologically purified in closed bioreactors. In the first stage of purification, an upstream denitrification process, microorganisms convert nitrate in the wastewater to elemental nitrogen; the second stage, which takes place in an aerobic membrane bioreactor, is nitrification in which ammonia is converted to nitrate. The activated sludge generated here is separated off directly in an ensuing membrane filtration step.

At the heart of both membrane separation steps are rotating disc filters developed at the Fraunhofer IGB and manufactured under license by Bellmer. Within a cylindrical housing a stack of ceramic membrane discs is set on a rotating hollow shaft. While solids and microorganisms cannot pass through the pores of the membrane, water can. The thus purified water collects inside the filter discs and drains off centrally via the hollow shaft. The highlight of the process is that the rotating motion of the filter discs – or rather the centrifugal force – ensures that the covering layer on the filter discs does not become too thick and that any sediment is sloughed off again. This allows trouble-free and economic operation.

“In respect of effluent quality and microbial contamination, the purified wastewater is so clean that you could bathe in it. It fulfills the European Bathing Water Quality Directive and can be pumped with a clear conscience into the nearby Leimbach stream – whose water quality is actually improved by the effluent,“ emphasizes Professor Walter Trösch, Deputy Director of the Fraunhofer IGB. The activated sludge from the membrane bioreactor together with the separated bleed from preliminary filtration is collected in a tank for further treatment at Heidelberg’s central sewage treatment plant. The high-performance modern digestion facility here, also developed by Fraunhofer IGB, is more efficient than conventional digestion towers and produces more biogas.

Neurott is not an isolated case but only one example. Although 93 percent of German households are now connected to centralized sewage plants by public sewerage systems, great differences still exist between old and new German states and between urban and rural areas. In other countries, e.g. in Eastern Europe, the numbers of settlements or villages without sewerage are even higher. Semi-decentralized plants for up to 1,000 or even 10,000 population equivalents are especially suited for rural areas because the costs are often lower than those for a connection to the central treatment plant.

The aim of protecting the environment is also achieved by the technically superior semi-decentralized plants. Rural areas, which are especially sensitive with regard to nitrates and phosphates, benefit in particular from degradation of the nutrient salts. In addition, it is possible – without large technical effort – to collect and utilize rainwater if desired or alternatively to let it seep it away, in order to counteract a sinking of the groundwater level.

Even if the plant in Heidelberg-Neurott is only small (100 population equivalents), it is the demonstration model for future urban sewage plants up to 50,000 population equivalents: “With industrially pre-manufactured modules of identical setup, reduced operating costs and highest effluent quality, it could become an export hit ‘Made in Germany’,“ says Walter Trösch.

The preliminary investigations for this project were funded by the Ministry for the Environment of the state of Baden-Württemberg. The results gained in laboratory and pilot plant scale were adapted to real technical scale lead-managed by the Fraunhofer IGB. Development and testing of the Heidelberg-Neurott membrane bioreactor wastewater treatment plant were carried out as part of the DEUS 21 project (”DEcentralized Urban Infrastructure System”), sponsored by the German Federal Ministry of Education and Research (BMBF).

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB