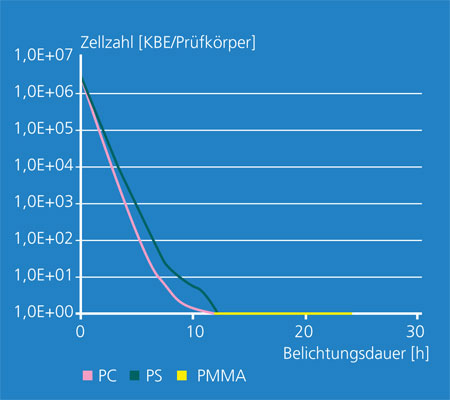

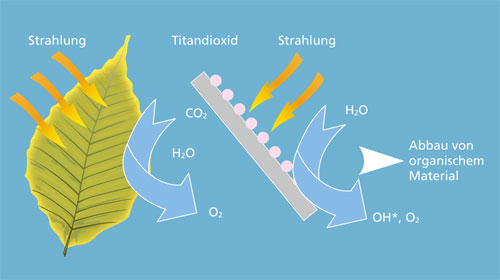

The samples consisting of various materials were produced using spray techniques, sol-gel processing, by compounding, PVD methods, spray pyrolysis or plasma sputtering. Of great interest from the microbiological viewpoint were the influence of the material properties, the method of coating and/or the equipment of the specimens as well as the impact of various proportions of photocatalyst on the inactivation of the various test organisms. The figure on the left shows an example in which three synthetic materials were examined. Here, with the test organism Sarcina lutea a distinct 5-6-log reduction of the cell count was achieved depending on the time. This corresponded to an inactivation of 99.999 to > 99.9999 percent.

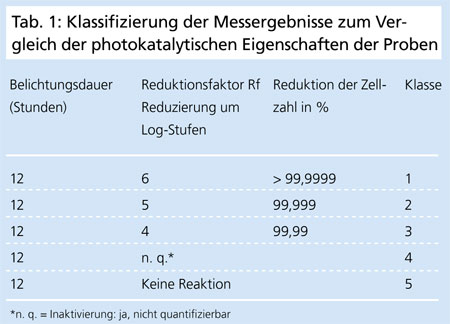

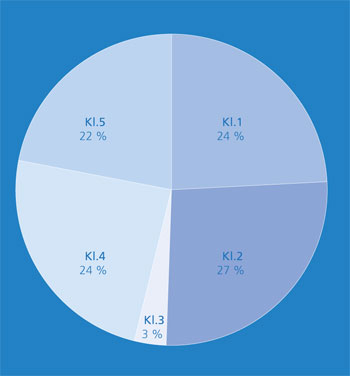

For all the measurement series carried out during the joint research project with the aim of characterizing the various surfaces, materials and thus the coating processes with regard to their antimicrobial properties, the endeavor was to achieve a quantification of the so-called reduction factor. The evaluation included all the results that were available from the characterization of the glass or synthetic material samples. In order to achieve a better comparability, the results available after a 12-hour exposure and with the Gram-positive bacterial standard test strain Sarcina lutea were taken as a basis. The resulting classification of the samples examined is shown in Table 1. As the initial cell count was generally set at 106, for example a reduction factor of 6 corresponds to the maximum achievable reduction of the microbial contamination under experimental conditions and thus to class 1.

About 50 percent of the photocatalytic surfaces examined with an observation time of 12 hours exposure come under classes 1 and 2.

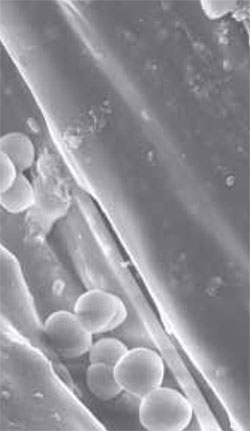

This means that at least 99.999 percent of the organisms used in each case on the samples examined are inactivated. In a further almost 30 percent of the coatings a reduction of the microbial contamination by 99.99 to 99.999 percent was still achieved. An inactivation based on photocatalytic activity could be detected both on glass and on various synthetic materials. The advantage for an industrial implementation can be seen in the fact that, adapted to the requirements, all the above-mentioned coating processes are suitable, thus opening up a wide range of applications for photocatalytic finishes. The precondition is a relatively uniform distribution of the particles constituting the photocatalyst. A complete decomposition of cell structures was not observed with the length of treatment examined. There is a need for further research here, especially regarding the degradation of fungal hyphae on surfaces.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB