Alternative: Plasma weathering shortens development times

In order to develop and market product innovations more quickly, Fraunhofer IGB develops together with industrial partners new testing methods that permit develop-ers to analyze the degradation characteris-tics of polymer surfaces, within a very short time and with a low consumption of ener-gy. These evaluations should be compara-ble to those obtained with the convention-al certified methods.

Imitation of natural weathering using plasma processes

Plasma-based processes are especially promising for weathering purposes. Here, the plasma serves as a source of radiation and particles. The effects of radiation, temperature, erosion and moisture, as well as the changes induced by them on the surfaces of polymers, can be obtained in a single process step with plasma processes. For the treatment the surfaces to be tested are placed in a specially adjusted atmosphere. By igniting a plasma, atoms and molecules are stimulated in the gas phase and partially ionized; existing molecules are fragmented and thus chemically activated. Many particles are stimulated in the plasma and relax under light emission, resulting in a broad electromagnetic spectrum. Radical chemical as well as photochemical reactions take place in the plasma phase and on the surface of the samples exposed to the plasma. If required, plasma ions can also be used to erode the surface. The composition of the plasmas can be controlled via the process parameters (pressure, plasma power, gas flow and gas type, duration of treatment).

Verification of the degradation characteristics just hours later

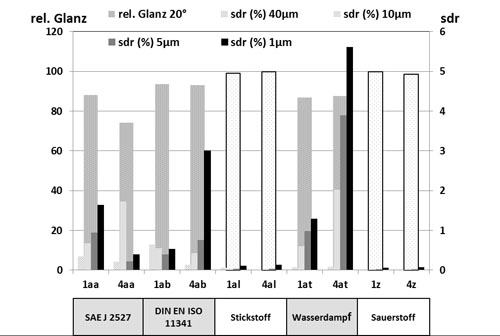

In studies carried out by the Fraunhofer IGB for Bayer Material Science, polyurethane paint samples were weathered in various plasma atmospheres such as e.g. water vapor plasmas. Weathering with the addition of gaseous water produces degradation to the surface after only 60 minutes, whereas with classical artificial weathering according to SAE J2527 degradation characteristics become evident only after more than 1000 hours. This shows that artificial and plasma weathering result in a comparable degradation pattern, here reflected in the measurements for surface roughness and gloss.

Project partner

Bayer Material Science, Leverkusen

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB