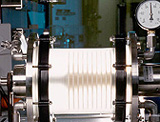

Scientists at the Fraunhofer IGB have developed a rotating disk filter, which efficiently controls the thickness of the particle layer formed during filtration by rotation of its filter disks. Hereby, the filter opens up new applications for membrane filtration such as industrial and municipal wastewater treatment.

The membrane disks of the rotating disk filter are preferably made of ceramic material. Ceramic material is characterized by high specific filtrate fluxes and good cleanability.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB