Aerobic biological wastewater treatment regularly produces primary sludge from mechanical pretreatment and excess sludge from nitrification and denitrification that has to be removed from the system and disposed of. Removal and reduction of sludge volume determine the sludge storage volume required, and thus the sludge disposal costs, which are a significant factor in the overall operating costs of a wastewater treatment plant. In the semi-decentralized wastewater treatment concept developed by the Fraunhofer IGB, the sludge storage volume can be optimally utilized through the introduction of a sludge management system. This is of especial interest for small sewage plants such as membrane sewage plants. The sludge management system is essentially based on

- the automated separation of the primary sludge by a solid sensor as well as

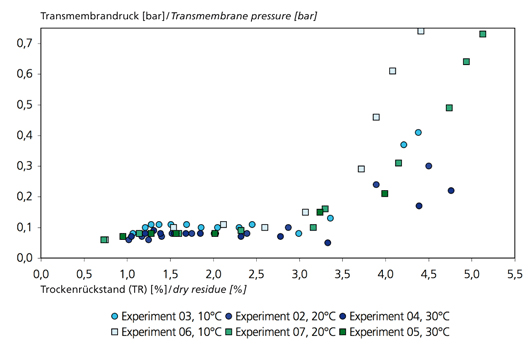

- the automated concentration and separation of the excess sludge with a rotating disk filter.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB