The EU and the state of Baden-Württemberg are providing around 5.9 million euros in funding for the construction of a biowaste refinery on the site of the municipal biogas fermentation plant operated by Abfallwirtschaft Rems-Murr AöR (AWRM) in Backnang. In the future, one ton of biowaste per day will be processed here into products and raw materials such as fibers, flower pots, fertilizer and biogas.

BW2Pro – Biowaste to Products

In the organic waste refinery "BW2Pro“, one ton of biowaste is to be processed daily into high-quality products and raw materials.

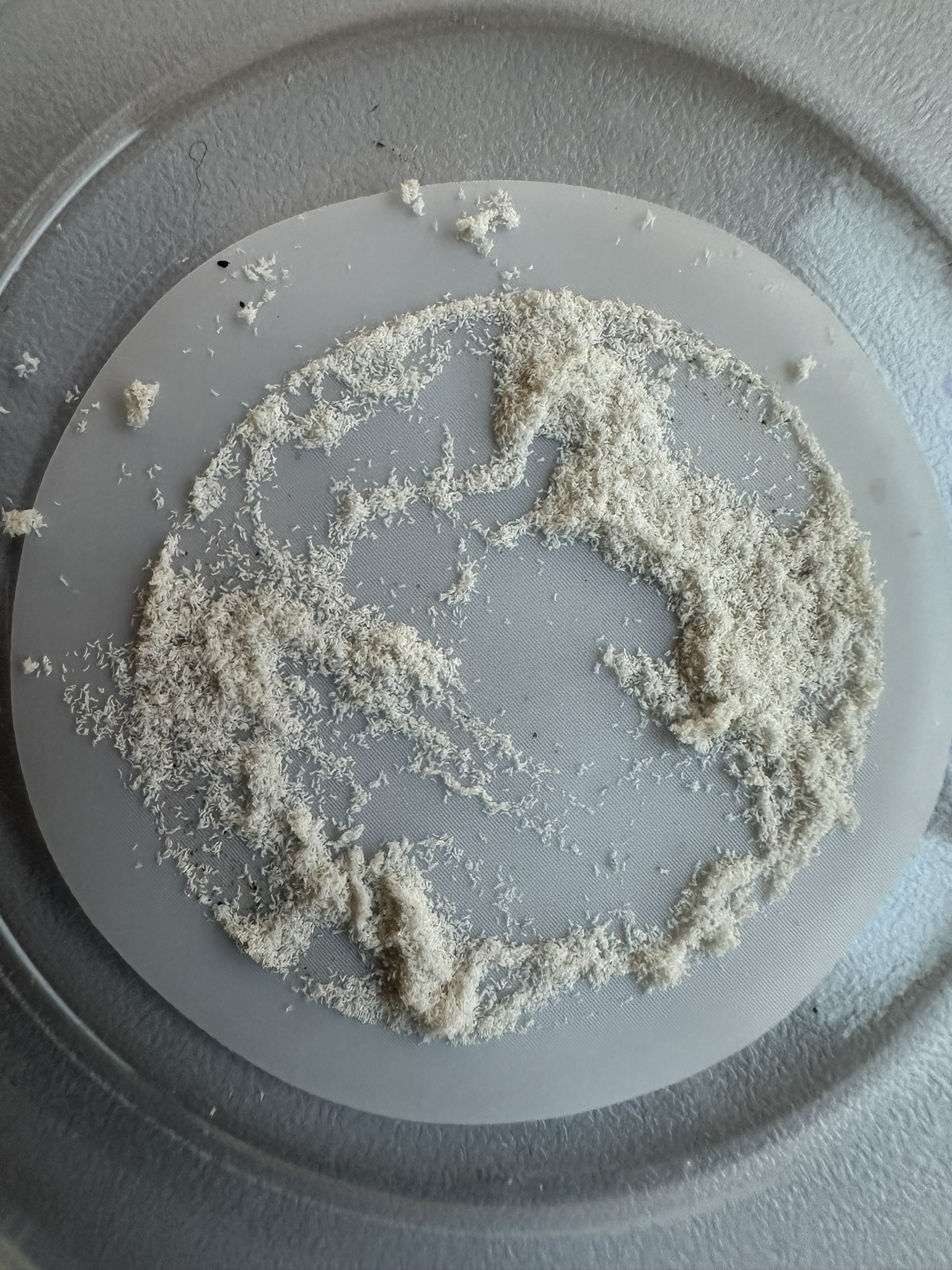

By means of high pressure and high temperatures, the biowaste is split and separated into a fibrous solid fraction and a liquid fraction. Almost all parts of the biowaste are further processed or used.

Medium fibers are pressed into products such as flower pots. Short fibers serve as a carbon source for the production of cellulase, which is contained in many detergents, for example.

The liquid fraction is fermented to produce biogas, and its digestate is used as fertilizer. Part of the liquid fraction is used to produce biodegradable bioplastics.

The BW2Pro project will be integrated on an already existing biogas plant of the Waste Management Rems-Murr. Waste Management Rems-Murr was involved in the planning of the project consortium at an early stage. Associations also support the project locally.

The project shows how biowaste can be recycled in municipal biogas plants. Here, the modular structure of the project is of great importance, as individual modules could be integrated on existing plants and thus the existing technology can be supplemented.

Results from Fraunhofer IGB

Nutrient recovery

The biowaste fermentation plant in Backnang, Germany, produces liquid fertilizer and compost, which are used locally. However, the products currently still have little market value. In order to be able to recover relevant quantities of nitrogen and phosphorus from digestate in the future for the economic production of a sustainable and transportable complex fertilizer, the sub-processes must be further researched and the process chain as a whole needs to be improved.

The research scientists succeeded in extracting various P salts from the liquid fertilizer. Almost 45 percent of the phosphorus contained in the liquid digestate (in particulate and dissolved form) was recovered in this way. In relation to the dissolved phosphorus, the recovery rate was 90 percent. Ammonium was then stripped with air at an elevated pH value. The experiments enabled the Life Cycle Assessment of a possible recovery as ammonium sulphate fertilizer executed by a project partner. . It was shown that in this way CO2 equivalents can be saved compared to the use of conventional fertilizer.

Production of microbial biopolymers from residual waste streams

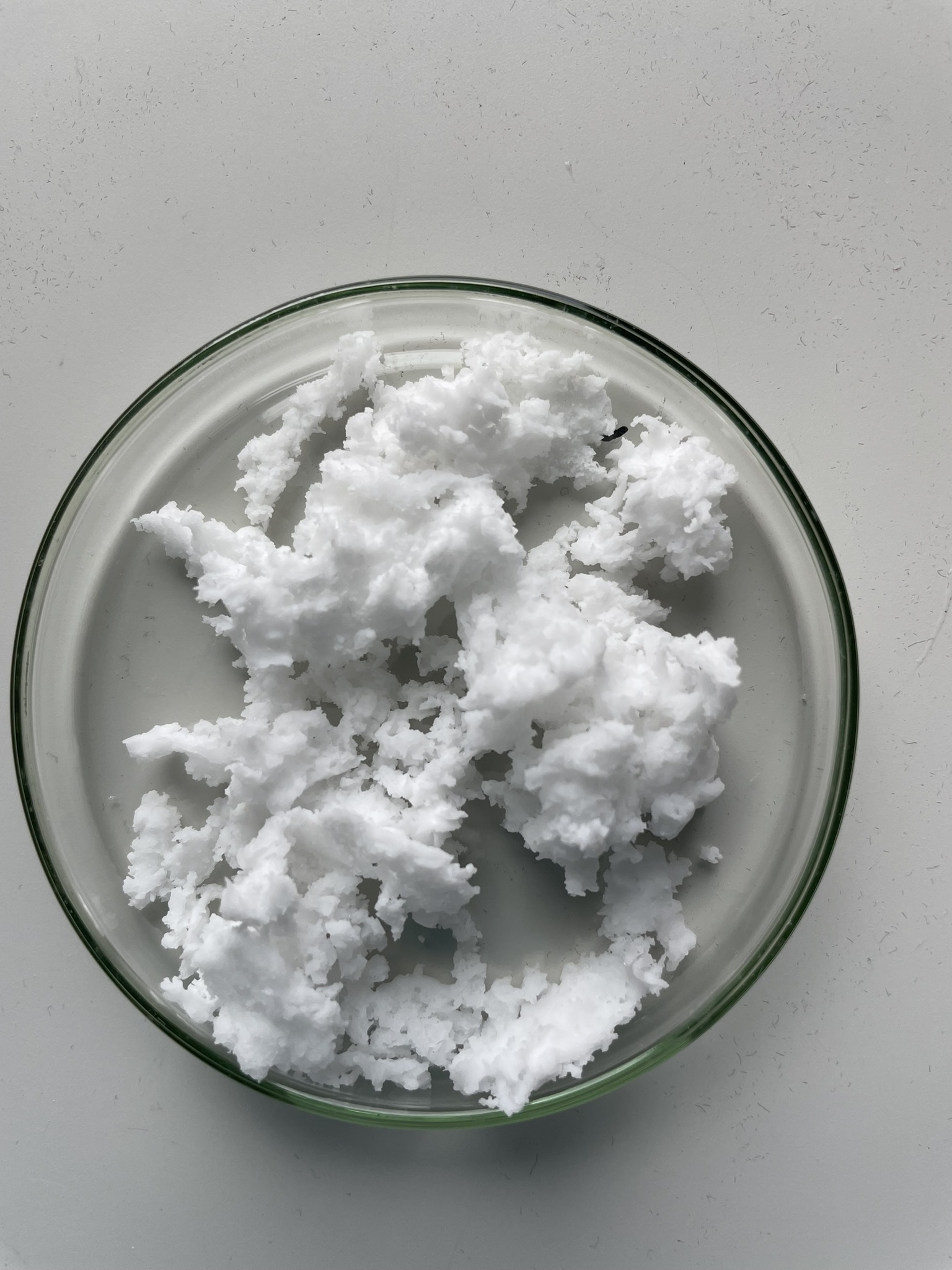

The aim of the project was the biotechnological production of polyhydroxyalkanoates (PHAs), which are microbially synthesized polyesters. In microorganisms, these biopolymers serve as intracellular carbon storage compounds: when a microorganism encounters an excess of carbon but its growth is limited by the deficiency of another essential nutrient, it stores the available carbon in the form of a PHA inside the cell. This natural mechanism is exploited by the researchers at IGB to convert various feedstocks into versatile PHAs using suitable bacterial strains. The type of PHA and its property profile are strongly dependent on both the substrate used and the microorganism. This enables the targeted development of polymers tailored to specific application areas by varying substrate and microorganism.

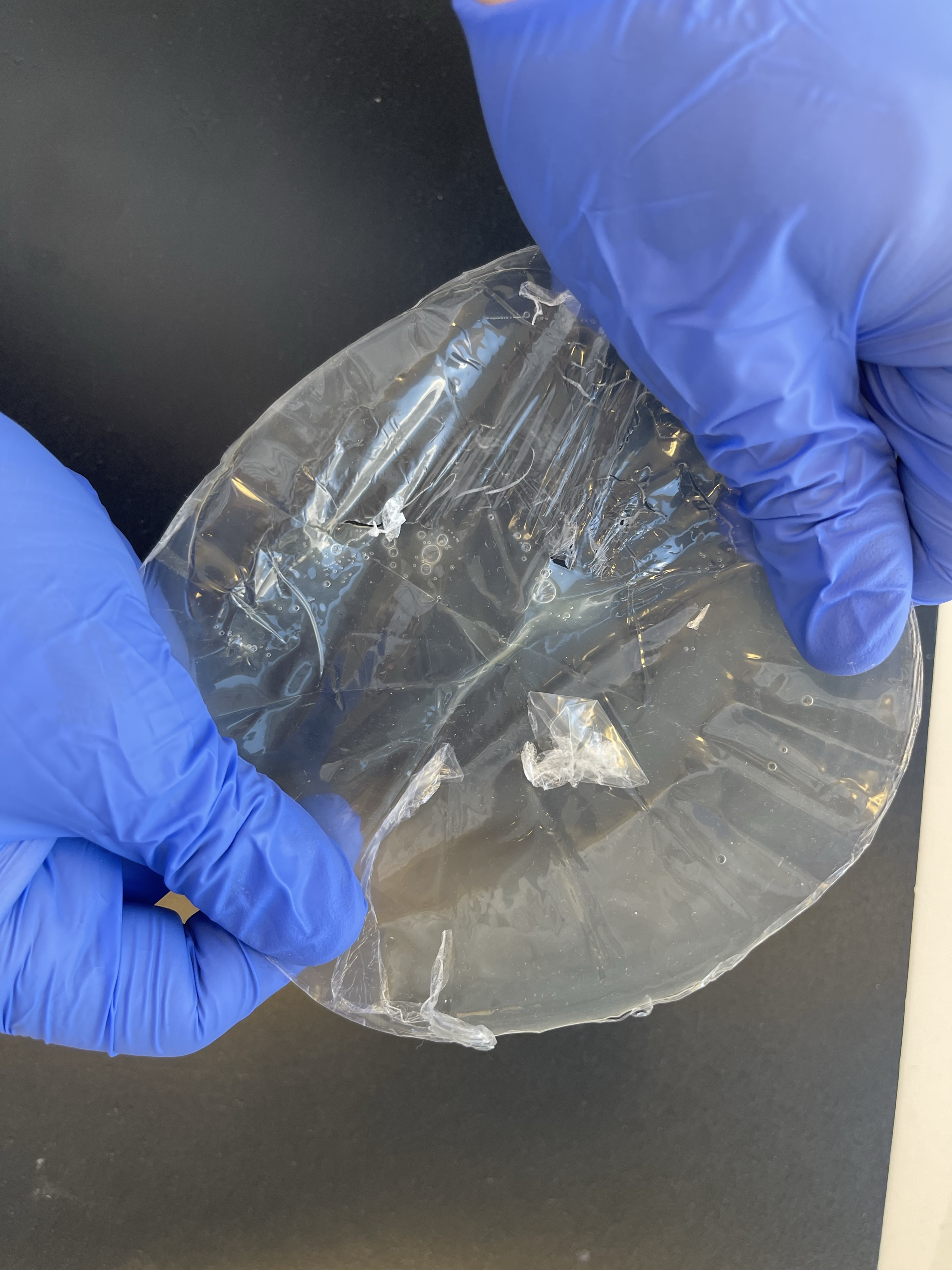

The focus of the project was the biotechnological production of polyhydroxybutyrate-co-hydroxyvalerate (PHBV) copolymer with a high valerate content. Unlike conventional polyhydroxybutyrate (PHB), PHBV offers enhanced flexibility, ductility, and thermal characteristics, particularly when synthesized with a high hydroxyvalerate (HV) content (> 20-30 percent). The objective was to optimize the fermentation and purification processes, scale them up to a 1000-L scale, and provide the project partners at the University of Stuttgart with samples for application testing.

Levulinic acid, a sustainably producible carboxylic acid derivative, was used as a carbon source in fermentation. The selected microorganism was Cupriavidus necator, capable of synthesizing the desired polymer from this substrate. The developed fermentation process also enabled feeding of concentrated thermal hydrolysate of biowaste, which contains various carboxylic acids and sugars as potential substrates for microbial conversion. This was successfully demonstrated at a lab scale. Additionally, the growth and toxicity test were performed in the microbioreactor system, particular attention was paid to the composition and proportion of carboxylic acids.

A production process for PHBV was successfully scaled up to produce sufficient sample quantities for processing by the project partner. The increased HV content in the PHBV copolymer results in a polymer that is both flexible and stretchable.

Current state-of-the-art PHA purification typically relies on halogenated solvents, which pose environmental concerns. One of the project’s goals was to replace these with green solvents to establish PHA production as a truly sustainable alternative to conventional plastics.

Using the developed fermentation and improved purification processes, more than 7 kg of raw polymer with an exceptionally high HV content (> 60 percent) was obtained from pilot-scale fermentation.

PHAs are biodegradable and suitable for a wide range of applications, including pharmaceuticals (e.g., biofilms, drug carriers, implants), the packaging industry (e.g., films and paper coatings), and agriculture (e.g., protective and mulch films).

Project information

Project title

BW2Pro – Biowaste to Products

Project duration

October 2021 – October 2024

Project partners

- BIOPRO Baden-Württemberg GmbH

- Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, Stuttgart

- Offenburg University of Applied Sciences, Faculty of Mechanical and Process Engineering

- ifeu – Institute for Energy and Environmental Research Heidelberg gGmbH

- NOVIS GmbH University of Hohenheim, State Institute for Agricultural Engineering and Bioenergy

- University of Stuttgart, Institute for Energy Economics and Rational Use of Energy

- University of Stuttgart, Institute for Interfacial Process Engineering and Plasma Technology

- University of Stuttgart, Institute for Plastics Technology

- Waste Management Rems-Murr (Associated partner)

Funding

We would like to thank the Baden-Württemberg Ministry of the Environment, Climate Protection and the Energy Sector and the European Union for funding the project "BW2Pro" as part of the ERDF (European Regional Development Fund) programme "Bioeconomy – Biorefineries for the recovery of raw materials from waste and wastewater".

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB