Services

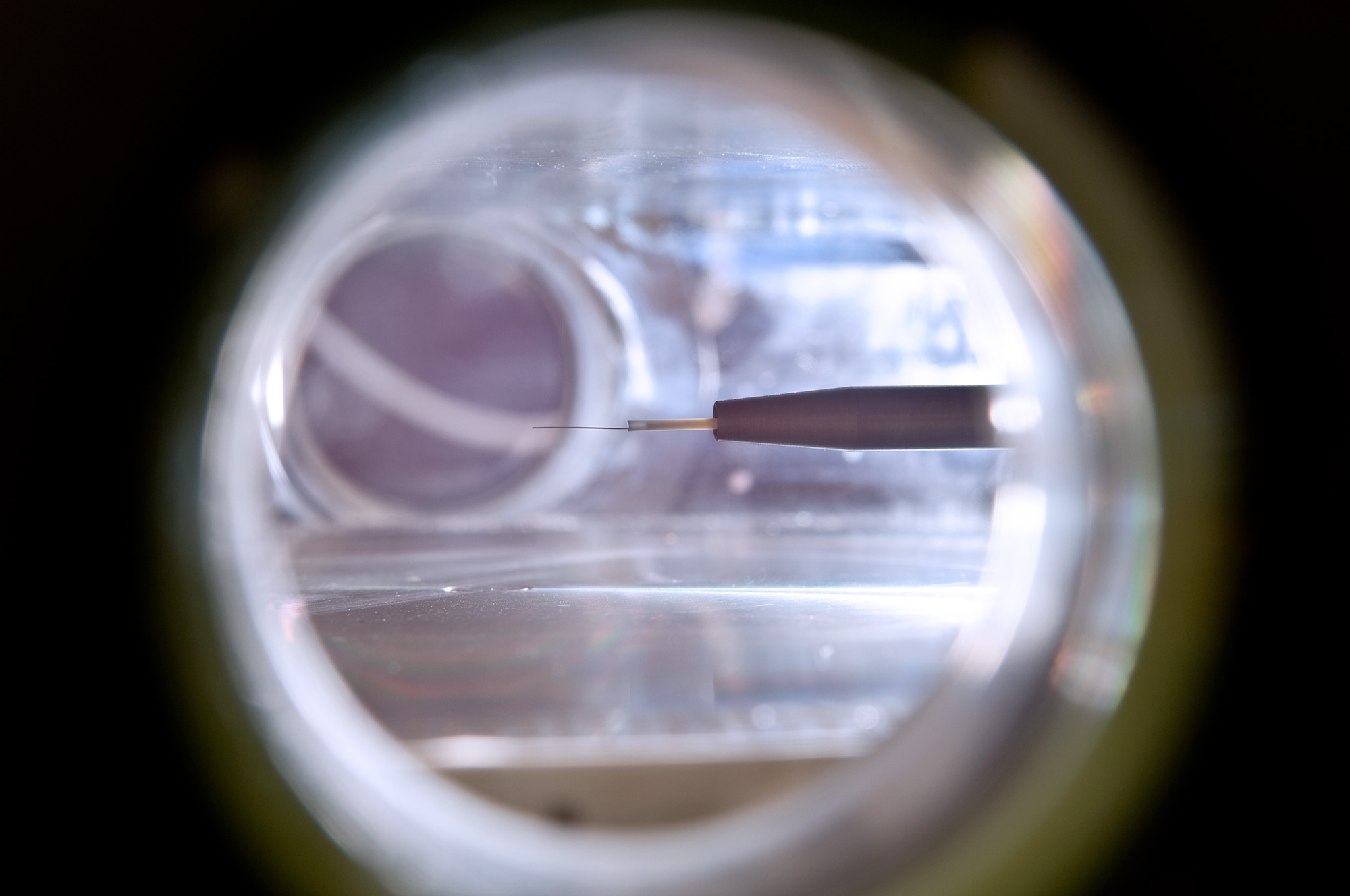

At the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, surfaces are first of all fully characterized with the aim of selectively modifying their properties, and in a second step, they are functionalized using various modification and coating technologies.

- Process development for the plasma modification of surfaces (powders, fibers, surfaces and shaped bodies)

- Layer development

- Scratch protection, abrasion protection layers

- Production of adhesive or dehesive agents

- Corrosion protection layers

- Barrier layers (e.g. impervious to oxygen and water vapor)

- Functionalization of surfaces

- Biofunctionalization, chemical functionalization

- Development of plasma cleaning processes

- Development of plasma sterilization processes

- Surface and layer characterization

- Geometry, morphology, roughness

- Chemical composition, biological properties

- Interfacial energy, adhesion

- Development of processes and plants

- Upscaling of the laboratory process

- Consultations, evaluation und feasibility studies to establish plasma methods as a technological alternative

- Patent and literature research on subjects relating to plasma technology

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB