Lignin is the largest natural, regenerative source of raw materials for aromatic compounds. However, the lignin produced in paper mills has so far not been used for material purposes but has been largely incinerated to generate energy. Alternative digestion methods such as the organosolv process, whose development is also monitored in our Group, can deliver lignins of higher purity and uniformity and thus make them interesting for new applications.

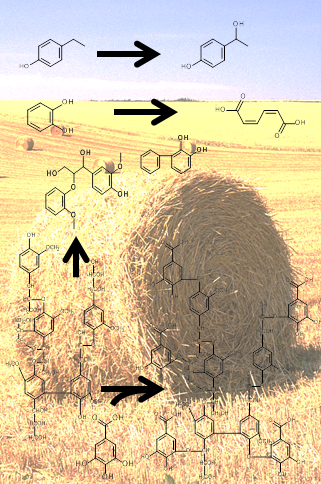

A material-industrial use of lignin requires a conversion of the raw material to suitable biosynthetic building blocks, which in turn can be polymerized to, for example, polyurethane or other plastics. However, the modification and degradation of the complex molecule lignin represents a major challenge, as it cannot simply be hydrolyzed enzymatically into monomers like cellulose and hemicellulose (see the area of competence of our "Saccharification of lignocellulose" group).

Insects, white rot fungi and bacteria are known for the natural degradation of wood and lignin-containing biomass. These organisms produce different enzyme cocktails which are needed to degrade the complex structure of lignin. So far there is no large-scale biotechnological process for lignin degradation and modification. An essential prerequisite for the future use of biotechnological, ecological processes for the utilisation of lignin is the availability of efficient and stable biocatalysts. Research at the Fraunhofer IGB is concerned with the search and characterization of such ligninolytic enzymes from fungi and bacteria.

Ligninolytic enzymes from fungi and bacteria

Suitable strains and combinations of strains (co-cultures) were cultivated and the expression performance optimized by different media composition and inductors in order to produce lignin-cleaving enzymes such as etherases or laccases and peroxidases in high amounts. In cooperation with the Fraunhofer CBP, the yield of ligninolytic enzymes in submers fungal cultures was further optimized and transferred to a larger scale of up to 10 liters.

In addition to fungi, ligninolytic bacteria are also considered. The bacterial strains were tested for the conversion of different aromatics and their ligninolytic enzyme activities in the supernatant. Intracellular enzymes of aromatic metabolism and new potential ligninolytic enzymes in the sequenced genomes of selected bacterial strains were identified. Bacterial peroxidases and oxidases could be actively expressed, purified and characterized. In further investigations, the catalytic properties of the enzymes were elucidated with regard to their potential for the modification of aromatics and lignin. Oxidation of ligin model substances and manganese by peroxidase could be shown. For the oxidase investigated, we observed oxidation of aliphatic side chains of aromatic monomers. Both enzymes can be used to modify lignin and lignin degradation products.

Functionalization of lignin using laccase

Furthermore, Fraunhofer IGB is concerned with the laccasecatalyzed functionalization of lignin with functional molecules. Here, organosolv lignin was activated and coupled with functional aromatics by means of laccase, whereby changes in the solubility of the lignin could be observed depending on the type of coupled molecule. Increased solubility in organic or aqueous solutions can be advantageous for certain applications.

Whole cell catalysis

Whole cell catalysis for the modification of lignin represents a further field of activity. In the course of the investigations of possible bacterial modification reactions, the ring cleavage of catechol was selected as particularly interesting. The cis-cis-muconic acid obtained can be hydrogenated to adipic acid, which in turn serves as a precursor for polymer chemistry. With the bacterial strain Rhodococcus sp. an almost complete turnover of catechol could be achieved within a few hours.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB