Di- and polyfunctional synthetic building blocks form the basis for the production of plastics. In recent years, research and industry have increasingly focused on biobased functional molecules. The best-known representatives of these biogenic materials include plastics based on starch, cellulose and polylactic acid (PLA). Vegetable oils and vegetable oil derivatives can also be converted into interesting monomer building blocks through appropriate functionalisation. In this research segment, Fraunhofer IGB focuses on the biocatalytic functionalization of vegetable oils or fatty acid derivatives to long-chain dicarboxylic acids (lcDCA) or vegetable oil-based epoxides. Dicarboxylic acids are used for example in the production of polyamides and polyesters. Vegetable oil-based epoxides can be used as PVC stabilizers, plasticizers, for the synthesis of biobased resins and coatings or, after further reaction, as components of lubricant formulations.

Bi- and polyfunctional synthetic building blocks based on vegetable oils

Dicarboxylic acids from vegetable oils

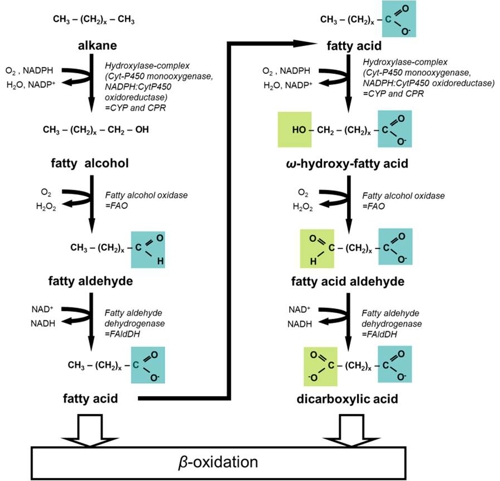

Synthesis and degradation of dicarboxylic acids

Long-chain dicarboxylic acids (C > 12) represent interesting synthetic building blocks for the production of biobased plastics and, in addition to their ecological advantages, offer the possibility of developing new polymers with special properties. However, they are chemically complex to synthesize, but can alternatively be produced biotechnologically. As substrate for the microbial synthesis of lcDCA, for example, alkanes, hydrolysed rapeseed oil or oleic acid from yeasts of the genus Candida can be converted.

The synthesis of long-chain dicarboxylic acids in microorganisms takes place via omega-oxidation, which is described for some yeasts such as the genus Candida or Yarrowia. In the course of three enzymatic reactions fatty acids are oxidized to dicarboxylic acids. The microorganisms also possess the biochemical degradation pathway for mono- and dicarboxylic acids, the so-called beta-oxidation, which prevents the accumulation of dicarboxylic acids in naturally occurring yeasts.

Goals and strategies: master and process development

At Fraunhofer IGB, new fermentation strains for the conversion of fatty acids into dicarboxylic acids are to be made available, which are easier to handle than the known pathogenic strain C. tropicalis due to their apathy. To provide new production strains, newly identified microorganisms will be used on the one hand as whole cell catalysts in an integrated process for the conversion of fatty acids in order to achieve the highest possible dicarboxylic acid yield. On the other hand, selected strains are genetically modified to enable dicarboxylic acid accumulation. These recombinant strains are also currently being investigated for their suitability as production strains. In addition, the potential uses of vegetable oils for dicarboxylic acid production that do not compete with the food industry are being investigated.

Results to date and outlook

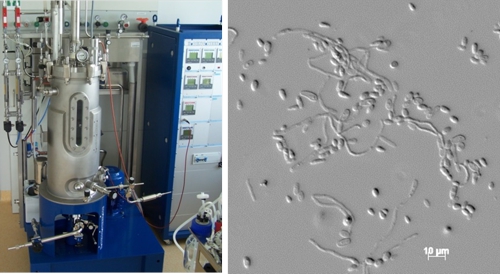

By developing different fed-batch processes with microorganisms of the genus Candida, dicarboxylic acid concentrations of up to 100 g/l from oleic acid have already been achieved. In parallel, we are investigating further microorganisms to provide new and easy to handle production strains that allow the highest possible dicarboxylic acid yield.

Currently, Fraunhofer IGB is working on the genetic modification of a Pichia strain. By specific deactivation (knock-out) of genes of the beta-oxidation pathway, the degradation of the dicarboxylic acids formed in this strain is to be prevented and the dicarboxylic acid yield is to be increased by increased activation of genes of the omega-oxidation pathway. This should provide a microbiologically safe production strain for dicarboxylic acid formation.

The process was developed using rapeseed oil derivatives and oleic acid as examples, but can in all probability be transferred to oils that are not used in the food sector. In a second approach, selected strains are genetically modified to ensure dicarboxylic acid synthesis. These recombinant strains are also currently being investigated for their suitability as production strains.

Range of services

- We offer fermentations to provide you with samples of 1,18-octadecenedioic acid produced by Candida sp.we also offer chemical-enzymatic modifications of 1,18-DCA, for example by epoxidation.we also have know-how in the field of strain development and can carry out the corresponding metabolic engineering on request

Epoxides from vegetable oils

Application and production of vegetable epoxides

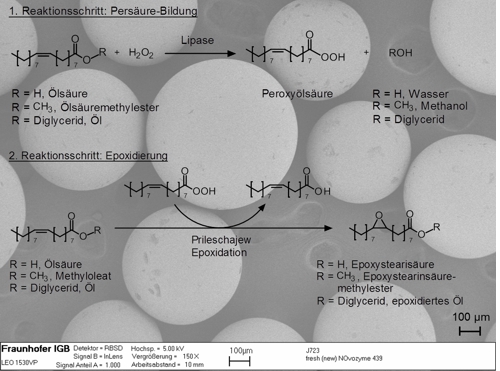

The epoxidation of unsaturated fatty acids and triglycerides results in products with increased polarity and reactivity. Vegetable oil-based epoxides are usually chemically produced on an industrial scale from soybean oil. The epoxidation takes place via the so-called Prileshaev reaction, in which olefinic double bonds of the unsaturated fatty acids are converted by peracid to the epoxide (oxirane). Peracid formation is often carried out in situ by reaction of hydrogen peroxide with acetic or formic acid using strong mineral acids, for example sulphuric acid, or ion exchange resins as catalysts. In chemical reactions, the main problems are the demanding process control due to a strongly exothermic reaction, strongly acidic reaction conditions and associated side reactions, as well as high salt content during product preparation.

An alternative to this chemical process is chemo-enzymatic epoxidation, in which a lipase enzymatically catalyzes the peracid formation from fatty acid and hydrogen peroxide. The main advantages are milder process conditions and a higher selectivity of the reaction. Undesired ring-opening reactions occurring in the chemical method can be largely avoided in the chemo-enzymatic process.

Objectives and strategies

Fraunhofer IGB is investigating the oleochemical use of oils and fats in various projects, with a further focus on the enzymatic production of epoxy building blocks for various applications. The focus is on the one hand on the identification of suitable biocatalysts and on the other hand on process development and scaling of the multi-phase reaction system together with Fraunhofer CBP in Leuna. When selecting the renewable raw materials to be used, special emphasis is placed on recycling non-food-relevant substrates.

Results to date and outlook

New enzymes

In a screening process at the Fraunhofer IGB, new, not commercially available enzymes were identified which catalyse the formation of peracids and thus, in a subsequent step, the epoxidation of unsaturated fatty acids. The enzymes are currently being characterized and examined for their technical application possibilities. In addition, a suitable immobilisation and, if necessary, enzyme modifications at the protein level could contribute to an increased activity and stability of the biocatalyst.

Process development

For the chemo-enzymatic epoxidation of vegetable oils and fatty acids we at Fraunhofer IGB mainly use vegetable oils which are not used as food. We were able to optimize the process for the conversion of different substrates by an immobilized lipase from Candida antarctica (Novozym® 435) with regard to substrate concentration, hydrogen peroxide addition, amount of enzyme used and temperature in such a way that various unsaturated fatty acids and oils are converted almost completely to the corresponding epoxides. Following the process development on a laboratory scale, the Fraunhofer CBP will enlarge the scale and develop process diagrams for a production plant on a technical scale and evaluate its economic efficiency.

Range of services

- We offer you screening for suitable enzymes for epoxidation.

- We also provide biotechnologically produced sample quantities of epoxides based on various vegetable oils, free fatty acids and fatty acid esters.

- Furthermore, we offer a detailed characterization of vegetable oil epoxides (thin layer chromatography, iodine number, epoxy oxygen content, FT-IR spectroscopy, rheology, dynamic differential calorimetry, gas chromatography) as well as

- Optimization of relevant process parameters by means of statistical design of experiments and

- Scaling up to the 100 litre scale.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB