Long-chain dicarboxylic acids – Intermediates for plastics

Long-chain dicarboxylic acids (C>12) are interesting intermediates for the synthesis of plastics with new properties. For example, dicarboxylic acids are used in the production of polyamides and polyesters. However, these are chemically complex to synthesize. Alternatively, long-chain dicarboxylic acids can be produced biotechnologically from the renewable raw material rapeseed oil. In rapeseed oil, fatty acids are bound to glycerine. After cleavage, the free fatty acids can be converted, for example, from yeasts of the genus Candida to dicarboxylic acids.

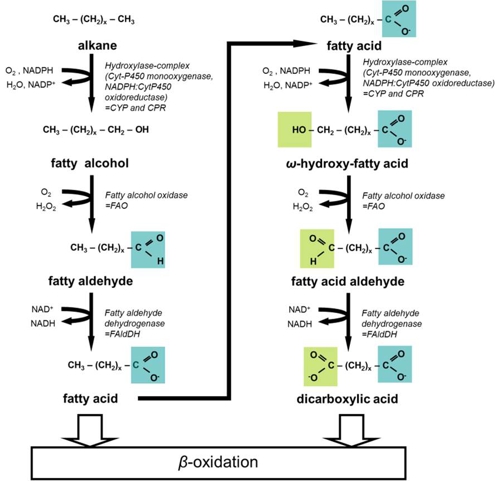

Synthesis and degradation of dicarboxylic acids

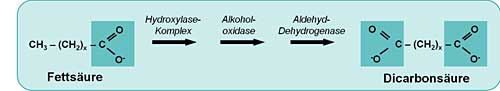

The synthesis of long-chain dicarboxylic acids in microorganisms takes place via ω oxidation, which is described for some yeasts such as Candida viswanathii oder Yarrowia lipolytica. In the course of three enzymatic reactions, fatty acids are oxidized to dicarboxylic acids. The microorganisms also possess the biochemical degradation pathway for mono- and dicarboxylic acids, the so-called β oxidation, which prevents the accumulation of dicarboxylic acids in naturally occurring yeasts.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB