In general, industrial biotechnology approaches provide access to many different substance groups in this segment. The institute has decades of expertise in the identification, modification and cultivation of microorganisms or the use of enzymes, which, coupled with know-how and technologies from the field of interfacial engineering, enable new products and applications. Examples of particularly interesting product groups are surface-active substances such as surfactants or biobased coating systems. We also focus on synthesis, downstream processing and characterization of substances and materials for which an interaction with biological systems plays an essential role. Examples here include additives for agriculture such as plant boosters made of microalgae, which positively impact cell growth in agricultural crops.

Fine and specialty chemicals

Our expertise in the field of biobased chemicals

Fermentation and purification processes have been successfully developed at Fraunhofer IGB for C2 compounds (ethylene, acetic acid, ethanol) and C3 compounds (propene, propanol, propanediol, propionic acid, lactic acid), for dicarboxylic acids (malic and itaconic acid, furan dicarboxylic acid), for amino acids or proteins such as thaumatin and bacteriorhodopsin.

Starting from renewable raw materials such as rapeseed oil or algae lipids, production routes for the biotechnological synthesis of basic materials for plastics production, such as long-chain dicarboxylic acids and triglyceride and fatty acid epoxides, were also identified. In the case of long-chain alpha-omega-dicarboxylic acids from oils, the process was optimized in such a way that subsequent purification is as simple as possible.

Other examples of biobased chemicals that have already been investigated at the IGB include aromatics, lignins, phenols and furans as well as extracts and their derivatives (terpenes, phytosterols and camphor) and gaseous and liquid hydrocarbons such as methane, olefins and long-chain alkanes.

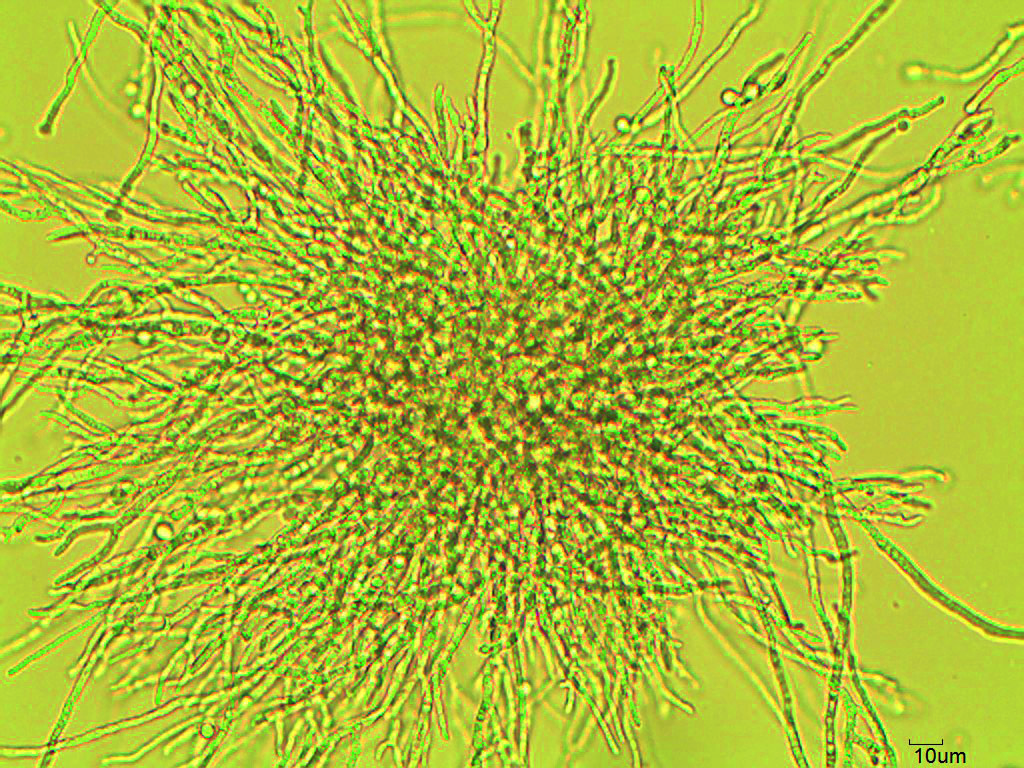

We have proven expertise in the microbial production of biosurfactants for use as detergents, emulsifiers and active ingredients in cosmetics, crop protection and technical applications. By optimizing the production process for mannosylerythritol lipids (MEL) and cellobiose lipids (CL) with pyrophytes of the genera Ustilago sp. and Pseudozyma sp. we were able to significantly increase the product concentrations of the biosurfactants discharged into the medium.

Reference projects

- Alliance Biosurfactants – Phase 2

- FDCAzymes – Lignocellulose based enzymes for the conversion of 5 hydroxymethylfurfural to 2,5 furanedicarboxylic acid (cbp.fraunhofer.de)

- Lignoplast – Functionalized lignin degradation molecules as platform chemicals (cbp.fraunhofer.de)

- 2GEnzymes – Enzymes for 2G Sugars (cbp.fraunhofer.de)

- BioFAA – Bio isobutene derived fuel additives (cbp.fraunhofer.de)

- KomBiChemPro – fine and platform chemicals from wood by combined chemical-biotechnological processes

- ChiBio – Chitin from fishery waste as a raw material for the production of specialty chemicals

Range of services at a glance

At Fraunhofer IGB we are engaged in the development of processes for the recovery of platform and fine chemicals from biogenic material flows. Questions on the efficient use of biogenic residual and waste streams are answered as well as the development of processes for the production of biobased chemicals and products. We investigate derivatized and functionalized raw products and the production of drop-in and platform chemicals as important intermediates or of fine chemicals and specialties.

With the competencies established at Fraunhofer IGB, a wide range of process steps for the development of procedures can be mapped. This combines processes for the supply and conditioning of raw materials, the isolation of material flows and chemical and biotechnological conversion. The development of chemical catalysts and tailor-made enzymes is established know-how at the IGB and can be used as a technology module for establishing suitable chemical and biotechnological processes for the conversion of renewable raw materials and biogenic residues. Processes for effective product separation and purification are also implemented.

With the pilot plants and scale-up facilities available at the IGB, developed processes can be validated and optimized for industrial implementation. We provide sample quantities in kilogram and ton scale for application-technical investigations. As a basis for further process and plant design on a demonstration or industrial scale, we carry out a techno-economic evaluation together with partners.

Biosurfactants

Two classes of biosurfactants that have also proven to be promising detergents, emulsifiers and active ingredients in cosmetics, crop protection and industrial applications are cellobiose lipids (CL) and mannosylerythritollipids (MEL). They are particularly formed by smut fungi of the genera Pseudozyma and Ustilago in larger quantities. Their antimicrobial properties also make them interesting for use in clinical and pharmaceutical applications.

However, industrial production of these biosurfactants still requires improvements in the yield during fermentation and in the reproducibility of the product composition. Fraunhofer IGB is working on this. The goals of our investigations are therefore, on the one hand, an increase in productivity and yield as well as the use of renewable raw materials as substrates.

Organic acids

Organic acids are used in numerous branches of industry as well as in the cosmetics industry and medical technology. Fraunhofer IGB is developing processes for the production of platform chemicals using renewable raw materials or CO2.

Fungal systems have proven to be particularly advantageous for the microbial production of malic acid and itaconic acid. Further processes have been established for xylic acid and furandicarboxylic acid.

At the Straubing site, in a subproject of the joint project EVOBIO, we have enabled the methylotrophic bacterium Methylorubrum extorquens AM1 to produce simple difunctional organic acids from methanol in a targeted manner using metabolic engineering. This enables the value-added use of green methanol from CO2 or synthesis gas.

Long-chain dicarboxylic acids from plant oils

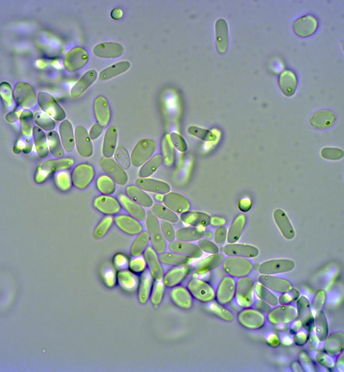

Long-chain dicarboxylic acids (C>12) are interesting intermediates for the synthesis of plastics with new properties. For example, dicarboxylic acids are used in the production of polyamides and polyesters. However, these are chemically complex to synthesize. Alternatively, long-chain dicarboxylic acids can be produced biotechnologically from the renewable raw material rapeseed oil. In rapeseed oil, fatty acids are bound to glycerine. After cleavage, the free fatty acids can be converted, for example, from yeasts of the genus Candida to dicarboxylic acids.

Interdisciplinary research field between Stuttgart, Straubing and Leuna

- Fraunhofer Center for Chemical-Biotechnological Processes CBP (cbp.fraunhofer.de)

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB